The HEAVY-DUTY AgriEuro THL A-PS 200 side flail mower with arm is an entirely Italian machine with an excellent quality and components.

This model represents the maximum level of flexibility of the flail mowers, in fact, the (totally hydraulic) movement is both horizontal and vertical. It can be used to clean street edges, banks and moats where it is requested that the flail mower works sideways to the tractor or even in vertical for the hedge and bush cutting.

- Ideal for municipal words, ditches, embankmets and inclined lands in general.

The hydraulic side shift is carried out by two sturdy pistons and the side transmission is made by 4 belts. Balanced electronic dynamics of the rotor and Comer gearbox with free wheel.

TECHNICAL DETAILS (in summary):

- Real working width: 200 cm

- Real width occupied (with side skids assembled): 214 cm

- Weight: 700 kg

STANDARD EQUIPMENT (in summary):

- Universal 3 point hitch of 1st category

- Boxed frame with anti-noise system

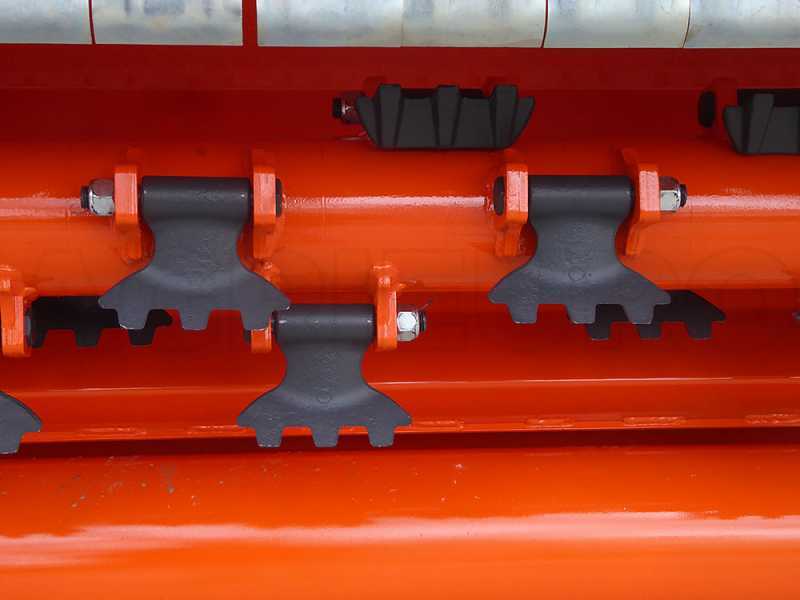

- Steel toothed hammer flails with M20 bolts

- Counter-blade blades

- Rear roller with large diameter

- Cardan shaft T60-120 cv L800 "Made in Italy by Comer"

- Rotation mechanisms on hardened steel bushings (Pcm)