The Italyco KV 3/90 screw compressor is an excellent product in the compressor sector. It belongs to the renowned Italyco product family with rotary screw system.

This sophisticated compressor not only offers impeccable long-term performance, but also extraordinary quietness, with a noise level of less than 65 db(A).

- Unrivalled performance: Guaranteeing a continuous flow of oil-free air of the highest quality, the Italyco KV 3/90 Screw Compressor stands out for its versatility. It is ideal for the most demanding and complex applications, finding use in a wide range of industries.

- Advanced Operation: The operation of the compressor is ingeniously designed: gas is sucked in through a duct created between the two rotors, then compressed and pushed towards the outlet. Thanks to an intelligent screw design, the pressure increases progressively, ensuring a constant flow of high-quality compressed air.

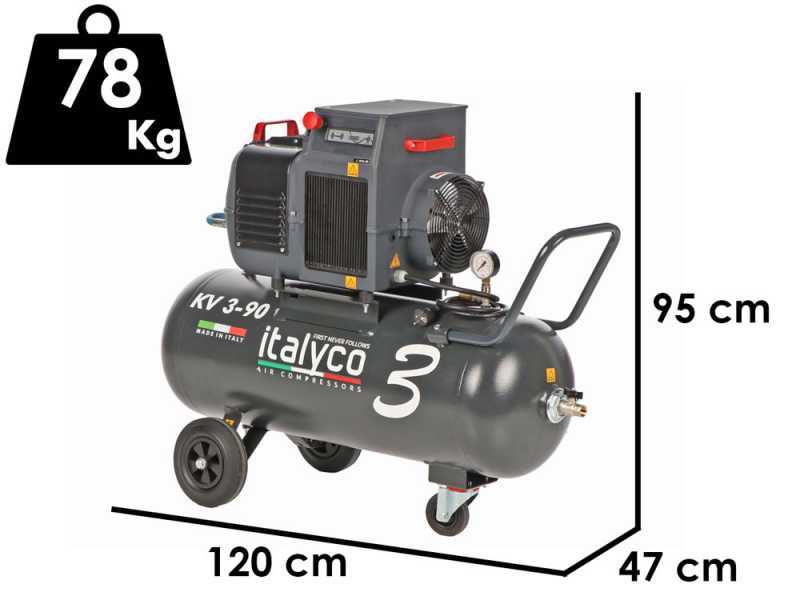

- Portability and Ease of Use: Equipped with three wheels, it is extremely manoeuvrable and can be easily transported anywhere. Compared to conventional piston compressors, the rotary screw system ensures greater efficiency and unrivalled performance.

- Power and Capacity: With a 90-litre storage tank and a production capacity of 270 litres of air per minute, this model offers an output of 2.7 kW and a maximum pressure of 10 bar. It is designed for heavy and continuous use, such as those typical of industrial and corporate environments.

- Application versatility: It is perfectly suited to a wide range of contexts including machine shops and industries, due to its ability to run continuously without any need for cooling.

- Easy Maintenance: The maintenance of this compressor is designed to be intuitive and simple, allowing the user to carry it out in a few quick steps. This ensures optimal operation over time, minimising downtime and maximising overall productivity.