The PLT-50 is entirely Made in Italy, ensuring the highest quality standards. It features a simple construction, the result of a precision engineering study confirmed by the tests made on different types of wood and more.

It is essential to consider approaching the pelletising process methodically, considering the different dynamics of pellet thermoforming (type and/or essence of wood, grain size, moisture content, and possibly natural soil conditioners), in order to obtain a quality pellet and a satisfactory production yield suitable for the Kwh of the machine used.

In order to obtain a high-quality pellet and maximum production efficiency, it is ALWAYS necessary to evaluate some factors regarding the wood:

- Moisture content: of the wood

- Grain size: of the wood

- Type of die plate: i.e. the right compression according to the type/essence of the biomass

Each type of wood reacts differently during the thermoforming process. It is indispensable to consider the wood pellet machine as a tool, so it is imperative to use the right one according to the wood processed, i.e. the right die plate compression.

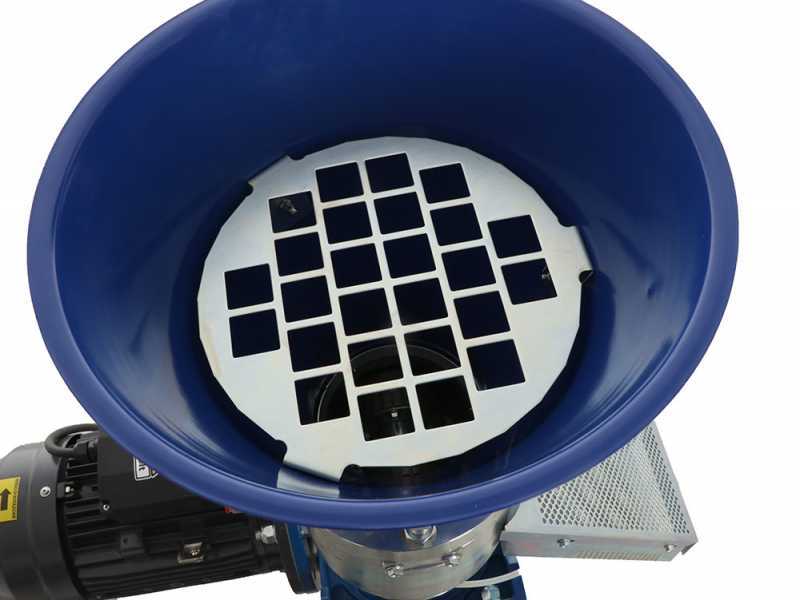

The correctly conditioned material is discharged from the die plate equipped with a material preloading part (inlet flaring), after which a cylindrical part (usually 6 mm diameter) will carry out the correct thermoforming of the product. This last part determines the degree of compression to give to the material to be pelletised.

The wood pellet machine is experiencing a steadily growing demand, as it was conceived as a consequence of the use of wood chippers, the disposal of green branches or carpentry waste.

Please note: sawdust and shavings from wood processing are excellent materials to be turned into pellets..

This machine will enable you to recycle the wood chips produced by your garden shredder or wood cutting machines in an extremely profitable way. You’ll be the able to to easily produce a high-quality energy-efficient fuel.